Digital Future

From Drafting Tables to Digital Models in Modern Design

Design has always been the bridge between ideas and reality. For centuries, engineers and designers relied on hand-drawn sketches to communicate intent, validate concepts, and guide manufacturing. Today, those same goals are achieved through sophisticated digital environments that connect design, engineering, and production into a continuous workflow.

The evolution from manual drawings to advanced digital models did not happen overnight. It reflects decades of technological progress, changing manufacturing demands, and a growing need for speed, precision, and collaboration. Understanding how modern design processes emerged and why they matter offers valuable insight for engineers, designers, manufacturers, and business leaders navigating increasingly complex product ecosystems.

Traditional Drafting and Its Inherent Limitations

Before computers entered the design office, drafting tables were the center of engineering activity. Products were defined through orthographic projections, sectional views, and meticulous dimensioning drawn by hand. These drawings were both technical artifacts and works of craftsmanship, demanding deep expertise and attention to detail.

However, traditional drafting imposed significant constraints:

- Manual effort and time consumption: Revisions required erasing, redrawing, and rechecking entire sheets, often leading to delays.

- Limited flexibility: Design changes late in development could cascade into weeks of rework.

- Interpretation risks: Drawings relied heavily on the reader’s experience, increasing the potential for miscommunication between design, engineering, and manufacturing teams.

- Storage and version control challenges: Physical drawings were difficult to duplicate, distribute, and manage across teams and locations.

Despite these drawbacks, hand drafting established the foundational conventions dimensioning standards, tolerances, and projection methods that still underpin modern design documentation. But as products grew more complex and timelines tightened, the industry required more adaptable tools.

The Shift to 2D CAD and the First Digital Leap

The introduction of 2D computer-aided design marked the first major transformation in design workflows. Engineers could now create digital versions of traditional drawings, maintaining familiar formats while benefiting from computational efficiency. Lines, arcs, and annotations became editable objects rather than permanent marks on paper.

This transition delivered immediate advantages. Drawings could be modified quickly, duplicated without degradation, and shared electronically. Layers allowed designers to manage complex information sets, and standardized templates improved consistency across projects. For many organizations, this era represented a pragmatic balance between established drafting practices and emerging digital capabilities.

At the same time, 2D CAD opened the door to specialized external support, with companies increasingly turning to cad modeling services to handle detailed documentation, legacy drawing conversions, and overflow work during peak development cycles. These services helped teams scale efficiently without sacrificing accuracy or standards compliance.

Yet, while 2D CAD improved productivity, it did not fundamentally change how products were defined. Designs were still representations of geometry rather than digital embodiments of physical objects. That deeper shift would come next.

The Rise of 3D Modeling and Parametric Design

The move from 2D drawings to 3D models redefined what design data could represent. Instead of describing geometry through views and dimensions, engineers began building virtual objects that mirrored real-world form and behavior. This transition fundamentally altered both the process and outcomes of product development.

Parametric modeling introduced intelligence into geometry. Dimensions became relationships, features were linked, and changes propagated automatically throughout the model. Adjusting a single parameter could update an entire assembly, associated drawings, and even downstream manufacturing data.

The benefits were substantial:

- Improved design intent capture: Models encoded functional relationships, not just final dimensions.

- Reduced errors: Automatic updates minimized inconsistencies between views, parts, and assemblies.

- Faster iteration: Designers could explore alternatives without rebuilding geometry from scratch.

- Better visualization: Stakeholders could evaluate form, fit, and function earlier in the process.

Industries such as automotive, aerospace, and consumer electronics quickly adopted 3D modeling to manage increasingly intricate products. Assemblies with thousands of components could be validated digitally long before physical prototypes existed.

Digital Tools as Engines of Collaboration and Speed

As modeling tools matured, they evolved from standalone applications into collaborative platforms. Modern design environments support concurrent workflows, enabling multiple contributors to work on different aspects of a product simultaneously.

Cloud-based data management systems allow teams to:

- Share models securely across departments and geographies

- Track revisions and maintain a single source of truth

- Integrate feedback from manufacturing, quality, and supply chain partners early in design

This shift has reduced the traditional handoffs that once slowed development. Instead of sequential workflows, organizations now operate in parallel, resolving issues when changes are least costly.

Digital simulation further accelerates progress. Engineers can analyze stress, thermal behavior, and kinematics directly within the design environment, validating performance before committing to tooling or production. What once required multiple physical test cycles can now be addressed through virtual iteration.

Transforming Manufacturing, Prototyping, and the Product Lifecycle

The impact of digital modeling extends well beyond design offices. Manufacturing processes increasingly rely on design data as direct inputs rather than interpretive references. CNC machining, additive manufacturing, and automated inspection systems consume 3D models to drive production with minimal manual intervention.

This integration enables:

- Faster prototyping: Digital models feed directly into 3D printers and rapid tooling workflows.

- Higher precision: Model-based definitions reduce ambiguity in tolerances and geometry.

- Streamlined change management: Updates propagate through design, tooling, and inspection plans.

- Improved lifecycle management: Design data supports maintenance, upgrades, and end-of-life planning.

Model-based enterprise approaches take this concept further, positioning the digital model as the authoritative source throughout the product lifecycle. Documentation, analysis, and manufacturing data all reference the same core definition, reducing duplication and misalignment.

Real-World Impact Across Industries

The evolution of design processes has reshaped how products reach market. In medical device development, digital models enable early validation of ergonomics and regulatory requirements. In industrial equipment, virtual assemblies help identify serviceability issues before equipment is built. In architecture and construction, integrated digital models coordinate disciplines and reduce costly on-site conflicts.

Even small and mid-sized manufacturers benefit from these advances. Access to modern tools and digital workflows allows them to compete on complexity and customization, responding quickly to customer needs without proportionally increasing overhead.

The Future Direction of Digital Design Workflows

Looking ahead, design processes continue to evolve toward greater integration and intelligence. Artificial intelligence is beginning to assist with generative design, exploring solution spaces beyond human intuition. Automation is reducing repetitive tasks, allowing engineers to focus on problem-solving and innovation.

At the same time, interoperability between systems remains a priority. As products span mechanical, electrical, and software domains, design data must flow seamlessly across tools and teams. Open standards and digital twins are emerging as critical enablers of this connected future.

What remains constant is the core objective: translating ideas into reliable, manufacturable products. The tools have changed dramatically, but the value of thoughtful, well-executed design has not.

Conclusion

The journey from hand-drawn blueprints to intelligent digital models reflects more than technological progress it mirrors the growing complexity and ambition of modern products. Each stage in this evolution addressed the limitations of the last, bringing greater accuracy, speed, and collaboration to the design process.

For engineers, designers, and manufacturers, understanding this evolution is not just historical context. It provides a framework for making informed decisions about tools, workflows, and investments that shape how ideas become reality in a digital-first world.

-

Celebrity8 months ago

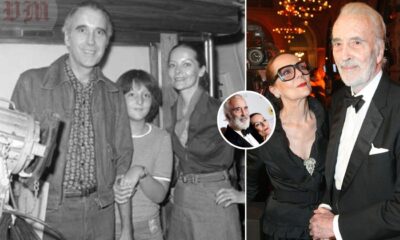

Celebrity8 months agoChristina Erika Carandini Lee: A Life of Grace, Heritage, and Privacy

-

Celebrity8 months ago

Celebrity8 months agoTrey Kulley Majors: The Untold Story of Lee Majors’ Son

-

Celebrity8 months ago

Celebrity8 months agoNick Schmit? The Man Behind Jonathan Capehart Success

-

Celebrity9 months ago

Celebrity9 months agoJamie White-Welling: Bio, Career, and Hollywood Connection Life with Tom Welling