Technology

Aircraft Inspections: What Happens Before a Plane Takes Off

Every time a commercial aircraft prepares for departure, it undergoes a rigorous series of inspections designed to ensure passenger and crew safety. These pre-flight checks aren’t just bureaucratic formalities, they represent the aviation industry’s unwavering commitment to keeping everyone who steps aboard an aircraft safe. Pilots and maintenance crews follow detailed protocols established by aviation authorities worldwide, examining everything from external surfaces to complex internal systems. What’s fascinating is just how thorough these procedures really are, involving both time-tested visual checks and cutting-edge diagnostic technology. The meticulous nature of these inspections helps explain why commercial aviation has become one of the safest ways to travel.

The Preflight Walkaround Inspection

The preflight walkaround remains one of aviation’s most fundamental safety procedures, and it’s performed by pilots before every single flight. During this inspection, pilots systematically examine the aircraft’s exterior, looking for any visible damage, fluid leaks, or irregularities that might compromise flight safety. They’ll inspect critical components, the wings, fuselage, landing gear, engines, and control surfaces, checking for signs of wear, corrosion, or structural damage. Pilots verify that all access panels are properly secured, antennas remain intact, and external lights function correctly.

Interior Systems and Cockpit Checks

Inside the cockpit, pilots conduct comprehensive checks of all aircraft systems, instruments, and controls before firing up the engines. This process involves verifying that flight control surfaces respond correctly to inputs, checking fuel quantity and distribution, and testing communication and navigation equipment. Pilots review the aircraft’s maintenance logbook to ensure all required inspections are current and any previous mechanical issues have been properly addressed. The flight management system receives programming for the planned route, and pilots confirm that navigation databases contain the latest updates.

Maintenance Inspections and Scheduled Checks

Beyond pilot, conducted inspections, aircraft undergo regular maintenance checks performed by certified aviation technicians at prescribed intervals. These maintenance inspections range from routine daily checks to comprehensive overhauls that can ground aircraft for weeks at a time. Daily inspections typically include checks of critical systems, fluid levels, and any items flagged by the previous flight crew. More extensive A-checks occur approximately every 400-600 flight hours and involve detailed inspections of specific aircraft systems and components.

Advanced Diagnostic Testing and Technology

Modern aircraft maintenance relies heavily on sophisticated diagnostic technology that can detect problems invisible to the human eye. Non-destructive testing methods, including ultrasonic scanning, eddy current testing, and radiography, allow technicians to examine internal structures without disassembling components. Engine performance monitoring systems continuously collect data during flight, enabling predictive maintenance that addresses issues before component failure occurs. When verifying critical system integrity, maintenance professionals rely on Ateq Aviation testing tools to ensure hydraulic systems, fuel lines, and pressurization systems meet strict safety standards. Advanced borescope cameras enable visual inspection of engine internals and other hard-to-reach areas without requiring extensive disassembly. Digital data analysis tools help maintenance teams identify trends and patterns that might indicate developing problems before they become serious. These technological advances have dramatically improved aircraft system reliability while reducing both maintenance costs and aircraft downtime. The integration of real-time monitoring and predictive analytics represents the future of aircraft maintenance, shifting from reactive repairs to proactive prevention.

Regulatory Compliance and Documentation

Aviation regulations require meticulous documentation of all inspections, maintenance activities, and repair work performed on aircraft. Maintenance teams must record every action taken, parts replaced, and test results obtained during their work. These records become part of the aircraft’s permanent logbook and must be available for review by pilots and regulatory inspectors. Pilots verify that all required inspections are current and properly documented before accepting an aircraft for flight. Regulatory authorities like the Federal Aviation Administration establish minimum standards for inspection frequency, procedures, and personnel qualifications. Airlines often exceed these minimum requirements with their own enhanced inspection protocols designed to maximize safety margins. Failure to maintain proper documentation can result in aircraft grounding, significant fines, and potential certificate suspensions. The aviation industry’s commitment to comprehensive record-keeping ensures accountability and provides valuable data for continuous safety improvements across the entire sector.

Conclusion

The extensive inspection procedures that occur before every aircraft departure demonstrate the aviation industry’s multi-layered approach to safety. From the pilot’s preflight walkaround to sophisticated diagnostic testing by maintenance technicians, each inspection serves as a critical safeguard against potential mechanical failures. The combination of human expertise, advanced technology, and rigorous regulatory oversight has made commercial aviation extraordinarily safe. These procedures continue evolving as new technologies emerge and safety data reveals opportunities for improvement. Passengers can take confidence knowing that every flight operates only after thorough verification that the aircraft meets the highest safety standards, standards established by decades of aviation experience and the continuous r

-

Celebrity8 months ago

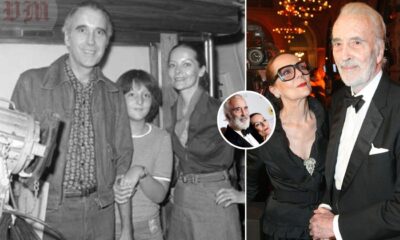

Celebrity8 months agoChristina Erika Carandini Lee: A Life of Grace, Heritage, and Privacy

-

Celebrity8 months ago

Celebrity8 months agoTrey Kulley Majors: The Untold Story of Lee Majors’ Son

-

Celebrity7 months ago

Celebrity7 months agoNick Schmit? The Man Behind Jonathan Capehart Success

-

Celebrity8 months ago

Celebrity8 months agoJamie White-Welling: Bio, Career, and Hollywood Connection Life with Tom Welling