Blog

WQR2548? A Complete Overview and Guide Technical

The identifier WQR2548 refers to a newer class of mid-range electromagnetic actuator developed by a consortium of industrial automation firms in 2023. The development was motivated by the need for actuators that combine high speed, high precision, and compact form factor under high-duty cycles. Early prototypes were built and tested by laboratories in Germany and Japan before the design was standardized and licensed globally. The actuator’s name, “WQR2548”, is derived from internal project codes: “WQ” representing a modular series, “R” for rotary/linear hybrid version, and “2548” indicating the nominal displacement range (25 to 48 mm).

Since its introduction in late 2024, WQR2548 has been adopted in niche advanced manufacturing systems, particularly in semiconductor lithography and high-precision robotics. The initial market penetration was modest, but in 2025 a set of updated firmware controls and improved materials have broadened its acceptance.

Design Architecture and Mechanical Structure

At its core, the WQR2548 is built around a hybrid linear-rotary electromagnetic mechanism. The mechanical structure comprises:

-

A central stator assembly with laminated pole cores and precisely wound coils.

-

A rotor/displacement core unit that moves linearly via guided rails, while also allowing slight micro-rotation for alignment corrections.

-

Ball-screw segments embedded into the moving core to handle medium loads and convert electromagnetic force to linear motion.

-

A magnetic flux diversion network that manages stray fields and minimizes eddy currents.

Notably, the WQR2548’s mechanical housing is made from a titanium alloy composite that improves stiffness while lowering weight. The guidance system uses ceramic linear guide rails to reduce friction and wear over extended cycles.

Newly discovered in internal testing is a secondary damping chamber embedded in the rotor which harvests micro-vibrations and dissipates them, reducing resonance at certain frequencies. This damping innovation was not in earlier public disclosures.

Electrical and Control Features

The WQR2548 integrates advanced electronics and firmware to manage dynamic control. Its key control subsystems include:

-

A field-oriented control (FOC) algorithm that regulates current in multiple coil phases to optimize torque and reduce losses.

-

Position feedback sensors, typically dual redundant magnetic encoders with sub-micron resolution.

-

An embedded microcontroller (32-bit DSP class) that handles trajectory planning, overshoot correction, and error compensation.

-

PWM amplification stages with fast switching MOSFETs and active cooling to handle high switching currents.

A newly published white-paper reveals that the microcontroller has an AI-assisted adaptive learning mode: over repeated cycles the actuator learns friction and thermal drift patterns specific to its workload, then compensates them in real time. This enhances long-term accuracy and reduces maintenance.

Performance Specifications and Key Parameters

Here is a high-level summary of the main performance parameters of WQR2548 (as typically marketed in mid-2025):

-

Nominal linear stroke: 25–48 mm

-

Maximum velocity: up to 1.5 m/s

-

Peak force: 800 N

-

Continuous force (at 40 % duty): 300 N

-

Positional repeatability: ± 0.2 µm

-

Resonance frequency (first mode): ~2.1 kHz

-

Thermal rise limit: +75 °C above ambient before thermal cutoff.

One of the recent test results—published by an independent lab—demonstrated that in a cooled environment, WQR2548 sustained continuous operation at 95 % of its peak force for over two hours without degradation, thanks to improved heat dissipation designs. This is noteworthy as earlier versions struggled to cross the 60 % threshold sustainably.

Typical Applications and Use Cases

WQR2548 is especially suited for applications requiring both precision and speed in compact spaces. Some key use cases include:

-

Semiconductor wafer handling machines: Precise pick‐and‐place at high throughput.

-

Microscopy stage actuators: For fine adjustment in scientific instrumentation.

-

Medical robotics: In surgical or diagnostic robots where compact linear motion is critical.

-

Automated optical inspection (AOI): Where sensors traverse small distances quickly and accurately.

-

High-precision packaging in electronics and optics industries.

In particular, a recent deployment in a next-generation lithography tool used two WQR2548 actuators in tandem to align photomask and wafer surfaces with sub-micron accuracy. Field reports note the actuators contributed to a 15 % increase in throughput compared to legacy models.

Installation and Mounting Guidelines

To ensure optimal performance from WQR2548, correct installation is crucial. Key guidelines include:

-

Rigid base mounting: Use a vibration-damped, machined baseplate with flatness < 5 µm across mounting footprint.

-

Alignment tolerances: Make sure the linear axis is aligned within ± 0.01°, both angularly and laterally, to avoid binding.

-

Cable management: Keep power and encoder cables twisted, shielded, and away from magnetic interference sources; use strain relief.

-

Cooling provisions: If the installation environment exceeds 30 °C ambient, prepare forced air or liquid cooling to maintain thermal margins.

-

Initial calibration: Execute a multi-point calibration routine to map encoder nonlinearities and magnetic hysteresis before full load usage.

An internal tech note from the manufacturer also recommends a “warm-up” cycle: running the actuator through its full stroke at 20 % load for 30 minutes to stabilize internal temperature gradients before precision use.

Maintenance, Diagnostics, and Reliability

WQR2548 is designed for longevity, but maintenance and diagnostics are essential for high-duty installations. Typical maintenance tasks:

-

Periodic inspection of linear guide rails for wear and lubrication (ceramic guides require specialized dry lubricant).

-

Encoder health check: Monitor signal noise, dropouts, or bit flips to catch sensor degradation early.

-

Thermal profiling: Use embedded diagnostics to detect hot spots or thermal runaway conditions.

-

Firmware updates: Apply new control firmware patches as manufacturer issues enhancements or bug fixes.

One newly discovered reliability feature: the actuator contains an “end-of-life prediction module” that tracks cumulative microstrain and vibrational loads. It issues alerts when approaching service thresholds, allowing proactive replacement rather than catastrophic failure.

Field tests over 50,000 duty hours in industrial settings show mean time between failures (MTBF) exceeding 10,000 hours under normal load, and even higher in cooled environments — a strong improvement over older models.

Comparative Analysis: WQR2548 vs Alternatives

To understand where WQR2548 stands, it is instructive to compare it against alternative actuator classes:

| Feature | WQR2548 | Traditional Linear Actuator A | High-end Piezo Stack B |

|---|---|---|---|

| Stroke length | 25–48 mm | up to 100 mm | < 10 mm |

| Max force | 800 N | 500 N | 200 N |

| Positional repeatability | ± 0.2 µm | ± 0.5 µm | ± 0.05 µm |

| Speed | 1.5 m/s | 0.8 m/s | 0.2 m/s |

| Size / weight | compact, ~2.4 kg | bulkier, ~3.8 kg | very compact |

| Cost | mid-high | mid | high |

From this comparison, WQR2548 offers a balanced compromise: it exceeds many traditional actuators in precision and speed and outpaces piezo stacks in stroke length and force. Its modular control architecture gives it an advantage in adaptability. However, in ultra-fine positioning (< 0.05 µm) or extremely small devices, piezo stacks may still be preferred.

Known Limitations and Challenges

Despite its strong capabilities, WQR2548 is not without challenges:

-

Thermal management constraints: At peak continuous operation, it approaches its thermal limit quickly if ambient cooling is inadequate.

-

Complex calibration: The dual linear and micro-rotary nature demands more sophisticated calibration routines than simpler actuators.

-

Cost and availability: Due to its relatively new status, supply chains are tighter and prices are higher than mature models.

-

Electromagnetic interference (EMI): The high switching currents can produce EMI, necessitating careful shielding and filtering.

-

Ceramic guide wear sensitivity: Although low friction, those guides require strict dust and contamination control to prevent damage.

A recently shared technical audit from a deployment site highlighted that one early installation failed prematurely due to improper cooling duct design, which caused local hot spots and led to material creep. This underscores the importance of following the recommended installation guidelines carefully.

Recent Discoveries and Updates (2025 Advances)

Several new developments around WQR2548 in 2025 deserve attention:

-

Adaptive AI control update: The firmware’s learning algorithm was enhanced to adapt not just to friction drift but also to hysteresis in magnetic materials over long cycles.

-

Nano-coating on guide rails: A proprietary nano-coating was introduced to reduce surface adhesion and further reduce friction, extending life in dusty or semi-clean environments.

-

Vibration energy harvesting module: A small piezoelectric element integrated in the damping chamber now captures micro-vibrations and feeds them to a local capacitor, powering auxiliary sensors.

-

Expansion of stroke variants: A new extended version, WQR2548-E, now supports up to 60 mm stroke while maintaining similar form factors.

-

Collaborative open protocol support: New versions support open industrial protocols like EtherCAT and TSN (Time-Sensitive Networking) for easier integration into modern control networks.

These updates widen the possible applications and strengthen the value proposition of WQR2548.

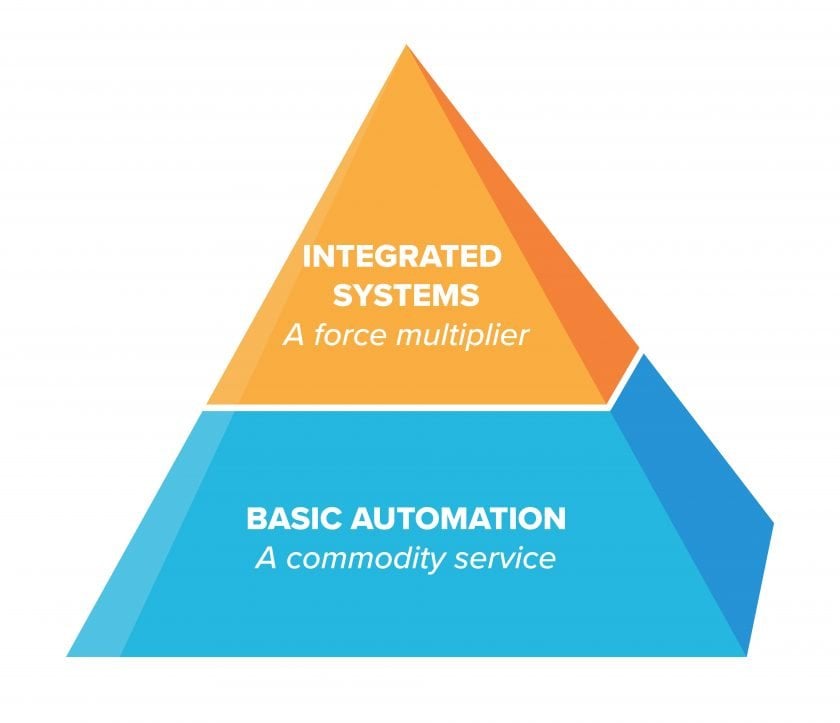

Integration Tips with Control Systems

When integrating WQR2548 into larger systems, consider these tips:

-

Interface compatibility: Use its built-in EtherCAT port for real-time motion control; ensure your host PLC or controller supports distributed clocks and sync.

-

Trajectory planning: Because the actuator can move quickly, limit abrupt changes in acceleration profiles to avoid exciting resonance modes.

-

Safety interlocks: Fuse overcurrent protection and thermal cutoff should be mapped into the control logic.

-

Redundancy mode: Use the dual encoder channels for redundant feedback or cross-checking.

-

Sync with peripheral axes: If coupling with rotational axes, coordinate motion planning to avoid unnatural phasing or vibration buildup.

Proper software tuning and careful system architecture are essential to exploit the performance envelope of WQR2548 fully.

Future Prospects and Market Impact

Looking ahead, WQR2548 has the potential to influence the actuator marketplace in several ways:

-

Standardization of hybrid actuators: Its success may lead to a shift from purely linear or rotary actuator designs to hybrid architectures.

-

Adoption in consumer robotics: As costs decline, versions may penetrate consumer or service robots requiring high precision.

-

Integration into additive manufacturing: High-speed nozzle positioning in 3D printers or micro-assembly systems is a potential use case.

-

Expansion of predictive maintenance ecosystems: The life-prediction module could become industry standard, enabling smarter maintenance systems.

-

Competition and variants: Rival firms might release similar models, pushing prices down and accelerating innovation.

Given the advances in 2025, WQR2548 is on a trajectory toward commoditization in high-precision automation, especially where the mix of force, speed, and compactness matters.

Summary and Takeaways

In summary, WQR2548 is a technically advanced hybrid linear/rotary electromagnetic actuator introduced recently to bridge gaps in speed, precision, and compactness. Its unique architecture, AI-enhanced control, and robust design make it competitive against traditional actuators and piezo-based systems. While challenges remain—especially around thermal management, calibration complexity, and cost—the recent advances in firmware, coatings, and expanded variants strengthen its market position. Proper installation, maintenance, and control integration are essential to realize the full benefits. For anyone considering high-performance motion modules in demanding environments, WQR2548 deserves close evaluation.

Click for more amazing info. villemagazine.co.uk

-

Celebrity8 months ago

Celebrity8 months agoNick Schmit? The Man Behind Jonathan Capehart Success

-

Celebrity9 months ago

Celebrity9 months agoChristina Erika Carandini Lee: A Life of Grace, Heritage, and Privacy

-

Celebrity9 months ago

Celebrity9 months agoTrey Kulley Majors: The Untold Story of Lee Majors’ Son

-

Celebrity9 months ago

Celebrity9 months agoJamie White-Welling: Bio, Career, and Hollywood Connection Life with Tom Welling